Our Custom Connectors Services

Tailored device connections and electronics housings

You have a challenge, we have the solution. We will support you throughout the product lifecycle, from the initial idea right through to the realization of your connection or housing solution. Our experience, built up over many years, guarantees that each new development will meet the stringent market requirements. Shape the innovations of tomorrow with us.

Customized Connectors

At RJCNE, a trusted custom connector manufacturer, we offer countless standard connectors that are sold to our customers on a regular basis. However, sometimes these products might not meet the specifications of your application or offer the same functions to satisfy your interconnect needs. RJCNE has the experience and expertise you are looking for: developing innovative customized design solutions. Within our business, 20% of the solutions we provide are custom electrical connectors that are meticulously tailored to the needs of each individual customer. We hope you will come to us for your next custom connectors!

Custom Design

At RJCNE, we pride ourselves on our ability to produce custom connectors and our flexible approach to modify our standard connectors; to meet specific customer requirements.

What sets RJCNE apart in the connector industry is our ability to manufacture ‘made-to-spec’ and full custom connectors at low and high volumes. This includes basic modifications to an existing product to clean-sheet design for a unique end solution.

We are able to move quickly from concept to production in just 12 weeks, with prototypes in as little as 4 weeks.

RJCNE can manufacture alternatives to competitor’s obsolete parts. There is no need to accept a Product Discontinuation Notification!

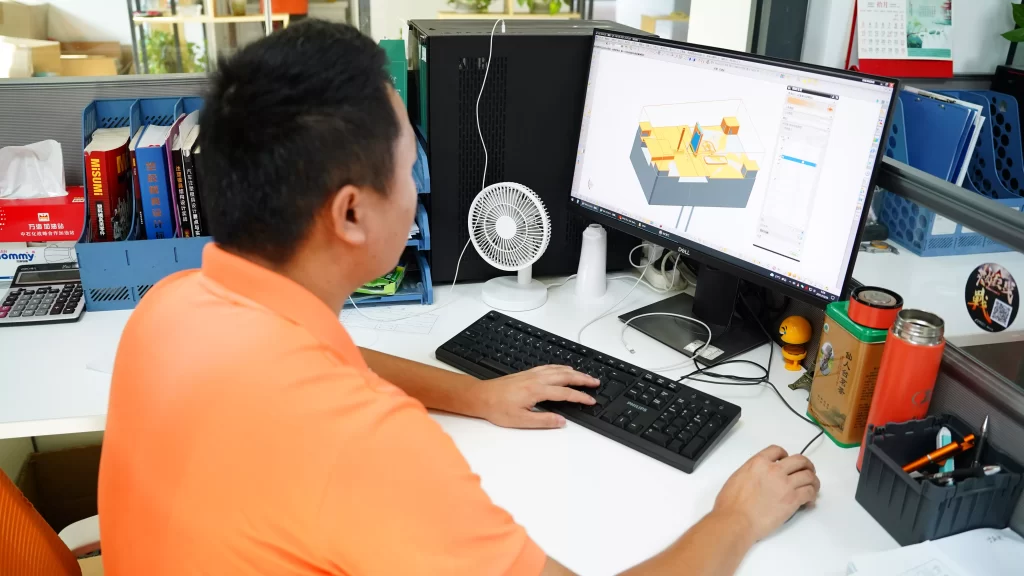

We have an experienced Engineering Team ready to build to a specification and produce models and drawings. Quick turn samples available based on 3D printing rapid prototyping.

Connector Customization Process

Whether you are looking for special designs or complex electromechanical system solutions, RJCNE will develop your tailored product using processes that have been proven many times over. From initial contact right through to series production and beyond, we will accompany you as your equal partner in turning your ideas into technical solutions and developing them.

Your advantages

- Experience built up over many years in the development of connection technology and electronics housings

- Flexible production planning thanks to our global presence

- Maximum customer focus when working on new product developments

- Fast decision-making processes and high economic security throughout the entire product lifecycle

- Proven and fast, with access to thousands of standard components

Preliminary clarification

Talk to us as your partner who understands the requirements and speaks your language. In the shortest time, we will provide you with:

- Personal consultation with experienced development engineers

- Joint technology workshops

- A technical concept, with inspection samples as an option

- A non-binding quotation

Conceptual design

Together, we will develop the best solution for your product in accordance with your specific requirements. Take advantage of the benefits of our proven conceptual design sequences:

- Coordinated and approved technical specification

- Regulated test plan, including laboratory tests and approvals

- Comprehensive documentation

Production-ready

Decades of experience and locations throughout the world enable flexible and absolutely reliable development sequences. Benefit from working with RJCNE through:

- High-level development and laboratory expertise

- Simultaneous engineering

- Standardized project management and quality assurance

- Application-specific standards and approvals

Production and logistics

We guarantee that your products will always arrive on time and in accordance with processes – regardless of batch quantity. Your advantages:

- High-level vertical integration and in-house tool shop and machine building facilities

- Flexible production planning, from manual assembly right through to mass production

- Customer-specific marking and packaging

- Global production and logistics network

Product lifecycle

Whether you are developing your products further, changing technical details, or want to discontinue them, we will accompany you throughout the entire product lifecycle:

- Certified quality and environmental management

- Holistic approach to the entire value added chain

- One contact person throughout the entire product lifecycle

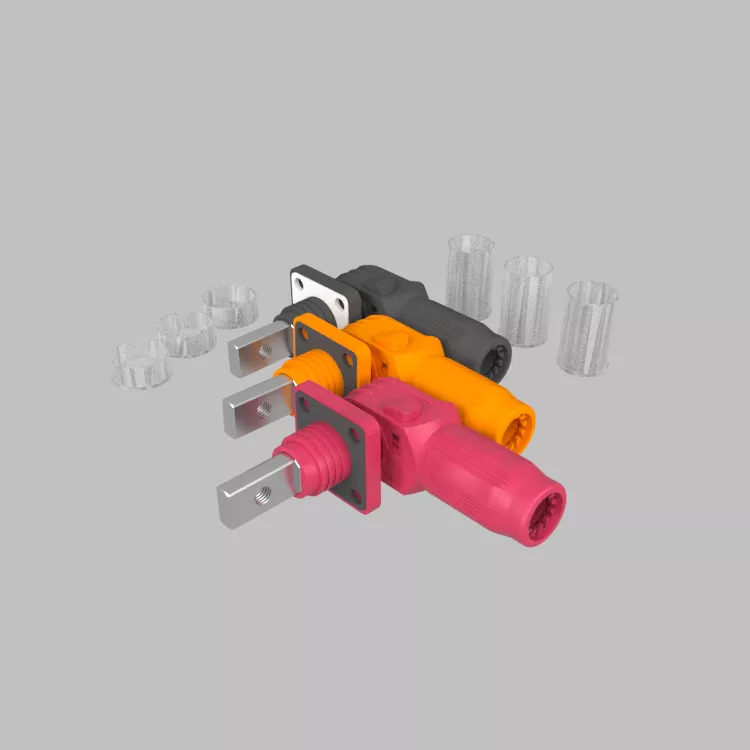

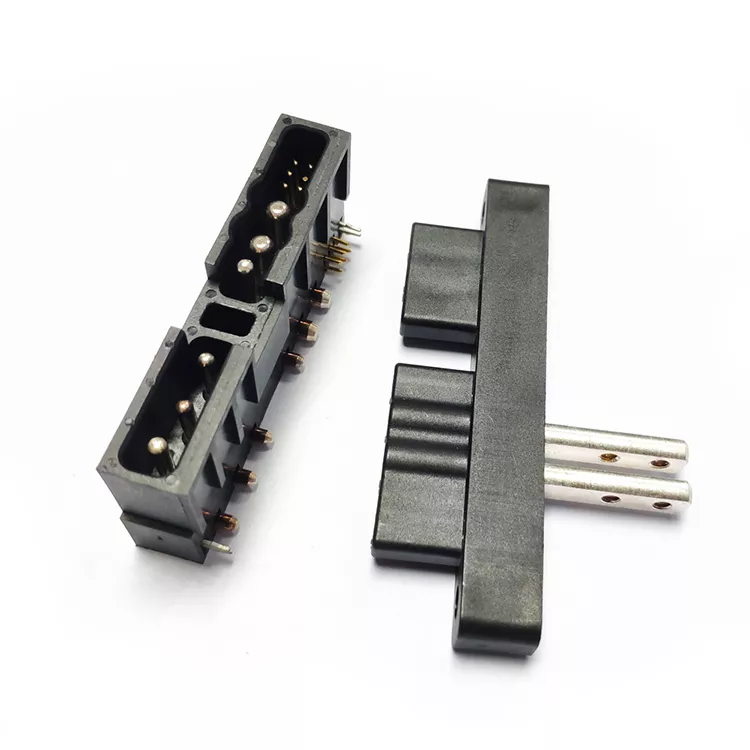

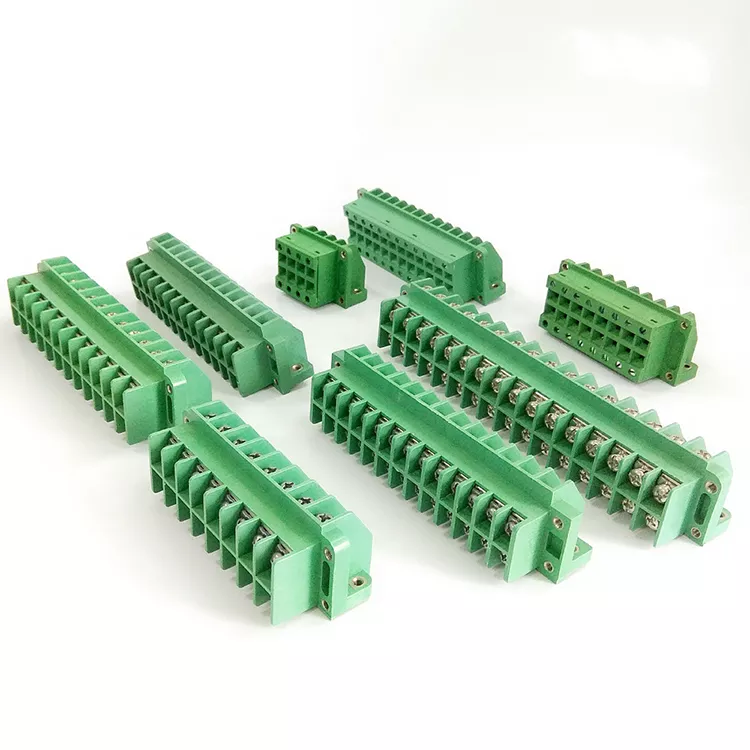

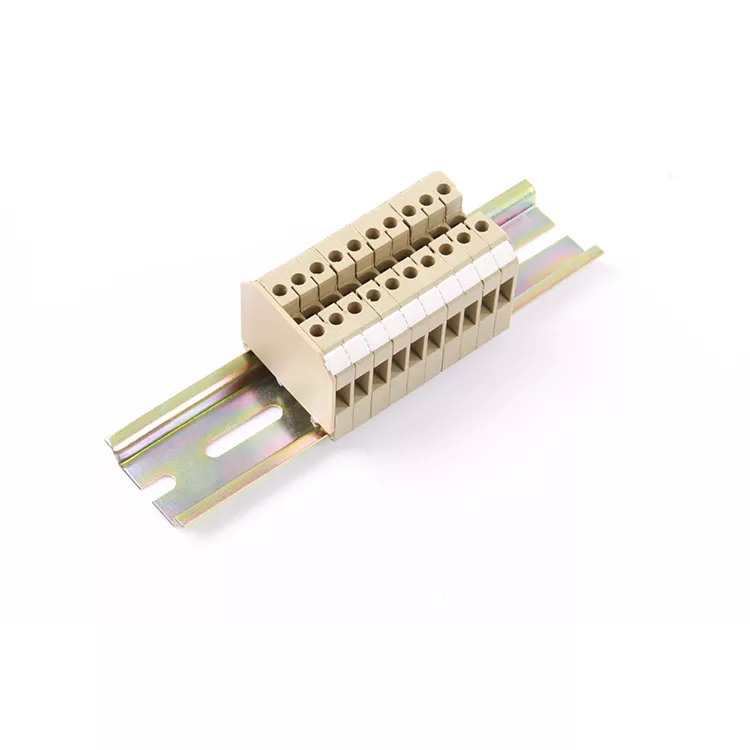

New customer-specific product developments

We will support you throughout the product lifecycle of your new customer-specific development. You will find examples for our product portfolio here: New energy vehicle connectors, power connectors, small current circuit connectors, terminal blocks, terminal blocks, etc., provide professional customized services.